Sharpening machines for circular saw blades

PowerStar 850

Flexible, CNC controlled machine for entry-level users

- Semi-automatic chamfering of the saw blade

- Adjustable chamfer angle

- Attachment for cutting in chip breaker grooves

solution K850-T

Fully automatic CNC machine

- Automatic grinding wheel insertion

- Automatic chamfering of the saw blade

- Attachment for cutting in chip breaker grooves

- Separation of machine set-up and machine operation possible

evolution K850-M

Service Center to start manless processing

- Fully automatic grinding, recutting and chamfering of the HSS saw blades

- Additional capacity due to unmanned running

- Consistent grinding quality with tight cost control

- Ideal solution for small to medium-sized companies

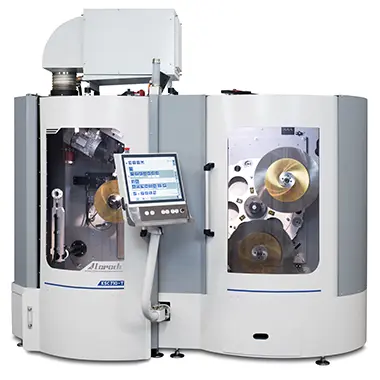

TWIN 860

Revolutionary 2-in-1 SOLUTION for grinding of:

- metal-cutting circular saw blades with CBN-abrasive grinding

- carbide tipped metal and wood circular saw blades

- Space-saving concept

- Two different grinding processes in ONE machine

- High degree of automation

- Excellent, uniform grinding quality

- Complete machining with only one grinding wheel

KSC 560-B

Entry-level machine for fully automatic

complete machining of metal cutting circular saw blades incl. automatic grinding of chip breaker slots

- Fully automatic grinding – Loading system with two stacks of finished and unfinished sawblades

- Ø 130 – 560 mm

- Complete machining of HSS- and TK-saw blades in one clamping operation

- Automatic grinding of chip breaker slots

- Prepared for use of cooling-oil

KSC 710-T

Service Center / Production Center with maximum possible degree of automation

- Fully automatic grinding including chamfering and cutting in of chip breaker grooves

- High capacity due to extra shifts and a large saw blade magazine with three or six blade stacks

- Consistent grinding quality with tight cost control

- Ideal High-Tech solution for service and production

SW 630–ST

Slot grinding

Cutting in chip breaker slots on metal cutting HSS- circular saw blades and carbide or cermet tipped blades up to 630 mm diameter

- Use of CBN grinding wheels and water coolant

- All control elements of the automatic slot grinder are clear and easily accessed

- Short set up and grinding times

SW 450

Low grinding volume demand

Conventional sharpening machine for grinding HSS and segmental circular saw blades with straight back tooth and curved back tooth

- Sharpening, retoothing and chamfering of metal circular saw blades